Improved energy conversion efficiency for new thermoelectric materials

2020-06-28

Researchers at Southern University of Science and Technology (SUSTech) have continued to improve thermoelectricity.

On June 8, Department of Physics Chair Professor Jiaqing He has led his research group to publish their recent research results in the high-impact academic journal Energy and Environmental Science (IF = 33.25). Their paper was titled “Realizing Record High Performance in n-type Bi2Te3-Based Thermoelectric Materials.”

In current energy cycle systems, more than 60% of energy is dissipated as waste heat. Low-grade and low-quality heat make up 50% of total waste heat. Thermoelectric (TE) technology can effectively gather and re-use low-temperature waste heat due to its ability to direct converting heat into electricity or vice versa. The practical applications of thermoelectric devices require both -type and n-type materials with comparable properties.

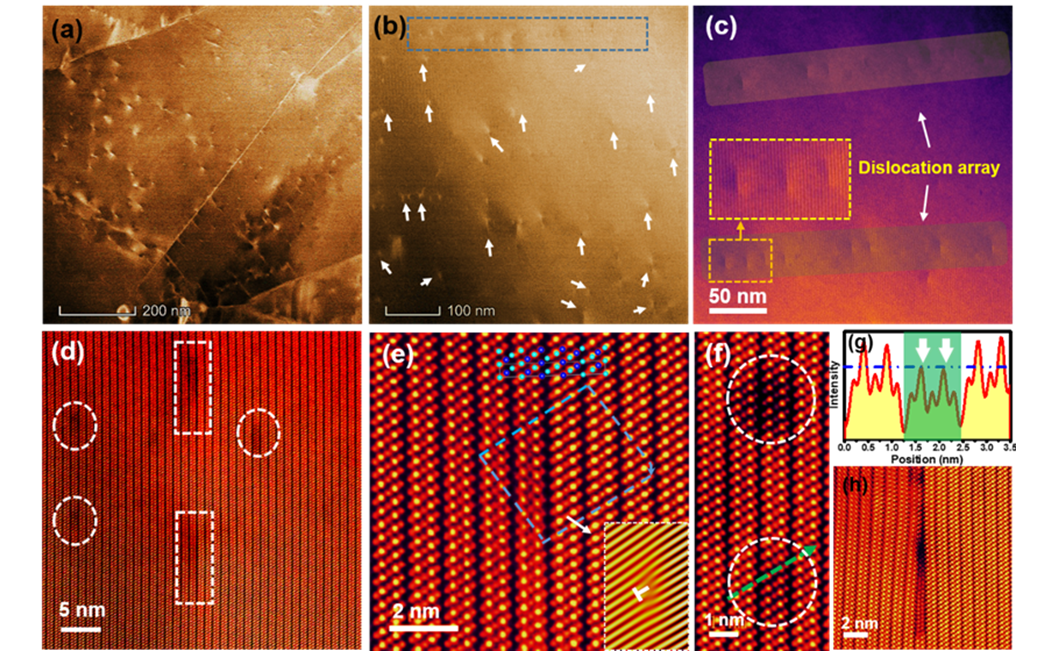

Figure 1 (a) Overview BF-STEM image of Bi1.8Sb0.2Te2.7Se0.3 15% Te sample. (b) The typical BF-STEM image shows the dislocation in the grain. (c) Enlarged image of blue frame area in (b), with dislocation arrays marked with red arrows. (d) HRTEM image shows lattice distortion, marked with white frames. (e) Enlarged image of the white frame area in (d). An edge dislocation vertical to this plane is evident. (f) Typical image showing a vacancy. (g) Intensity image of atoms marked with arrows in (f). (h) Typical edge dislocation showing two layers of atoms inserted.

Bismuth-telluride (Bi2Te3) based thermoelectric materials are a promising, environmentally friendly material to gather low-grade waste heat. It has been commercialized for a wide range of applications in power generation and refrigeration. Their applications have been severely hindered by the poor n-type samples.

The researchers used liquid phase sintering techniques to introduce dislocation arrays, as shown in Figure 1. On the one hand, these dislocation arrays enhanced the texturing, improving mobility. On the other hand, the dislocation arrays also provided potential wells in the conduction band, which could localize the low-energy electrons.

Based on this result, they further doped the Bi sites with antimony (Sb) atoms to optimize the carrier concentration and introduce multi-scale phonon scattering mechanisms. It significantly decreases thermal conductivity. As a result, a peak ZT value of ~1.4 was obtained in the Bi1.8Sb0.2Te2.7Se0.3 15 wt% Te sample, which, to the best of their knowledge, is a record-high value in n-type Bi2Te3–based alloys as shown in Figure 2(b).

The researchers also prepared commercially viable applications of their Bi2Te3-based thermoelectric materials. Their segmented device could achieve a high output power with a record thermoelectric energy conversion efficiency. It exhibited an 88% performance improvement compared to commercial ZM-based modules, as shown in Figure 2.

Figure 2 (a) The schematic of carrier localization; (b) Temperature dependence of ZT value for advanced n-type Bi2(TeSe)3 alloys; (c) and (d) The output power and energy conversion efficiency of the 70 legs TE module in this work.

Department of Physics postdoctoral researcher Bin Zhu, masters’ student Xix Liu, and Department of Materials Science and Engineering postdoctoral researcher Qi Wang was the co-first authors of this paper. Chair Professor Jiaqing He is the corresponding author, with SUSTech as the correspondent unit.

They received support from the Leading Talents of Guangdong Province Program, the Science and Technology Innovation Commission of Shenzhen, the National Natural Science Foundation of China (NSFC), and the Shenzhen DRC Project.

Paper link: https://doi.org/10.1039/D0EE01349H

He Jiaqing team homepage: http://jqhphy.sustech.edu.cn/